Category: HBX-ST for DX and Overfeed Systems

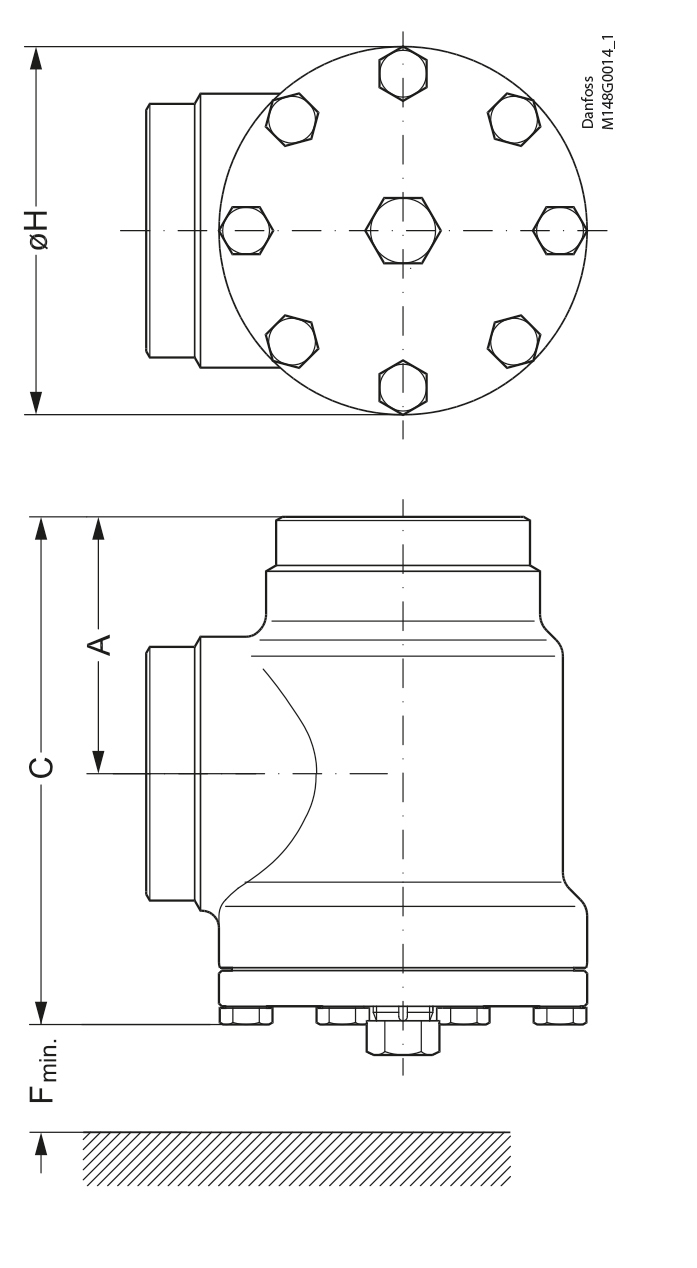

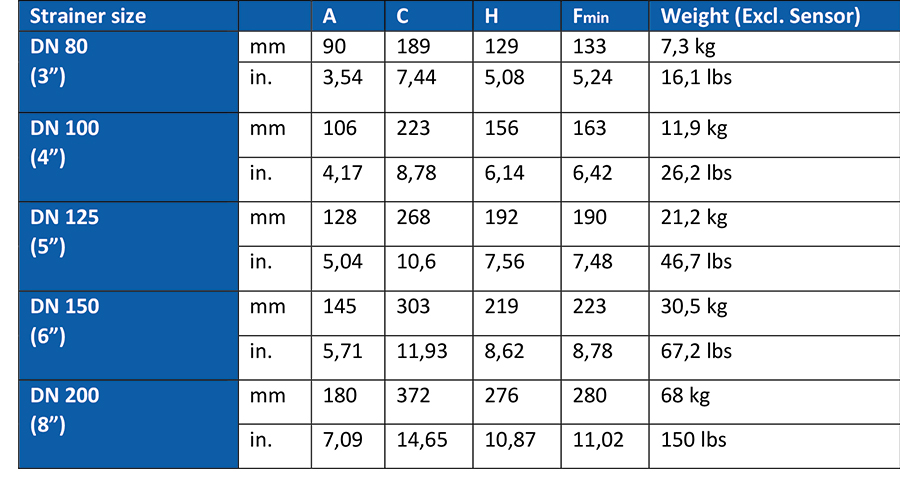

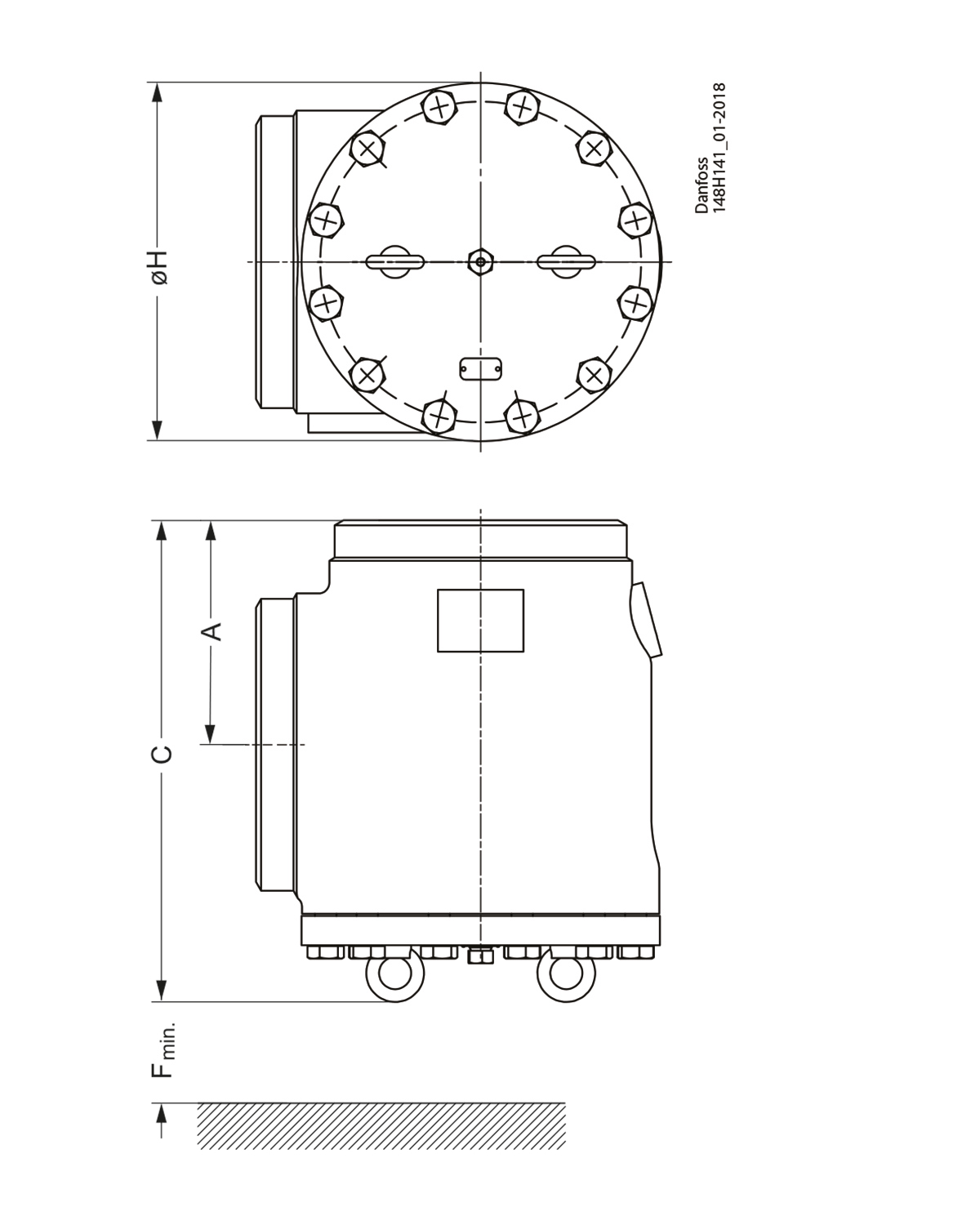

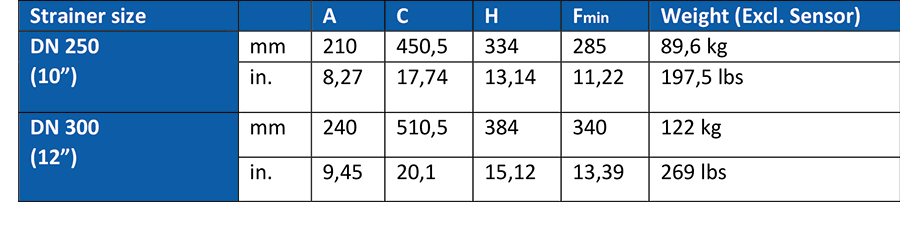

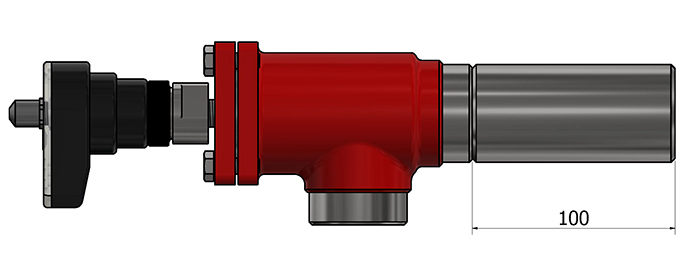

With a vapor quality sensor integrated into a standard strainer house you are ensured safe functionality of the sensor and easy installation. The butt-welded connection makes it easy to weld with same size of piping.

Please be aware that the flow direction of the vapor quality sensor is opposite of the flow direction when used as a strainer. If installed with wrong flow direction functionality will NOT be correct.

Besides the benefit of easy installation this solution makes it easy to dismantle the lid with the sensor conductor and clean it if necessary.

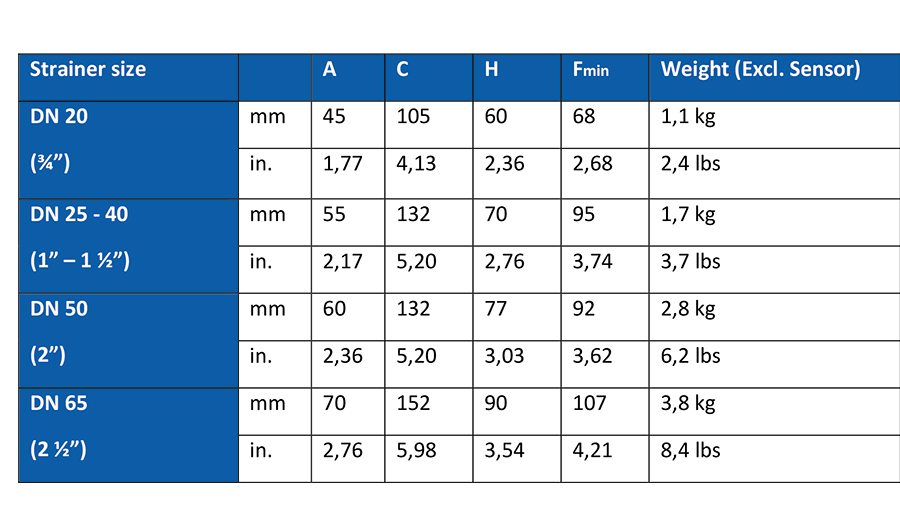

The sensor integrated into standard strainer housing is available in both carbon steel DN20 to DN300 and stainless steel DN20 to DN65. Ask for availability if size outside of this range is requested.

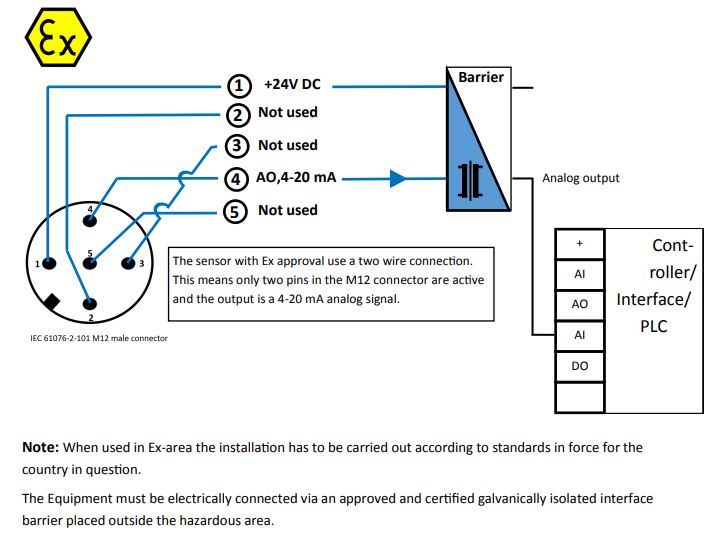

Intrinsically Safe design:

Intrinsically Safe (IS) sensors are designed and wired to work on such a low current and voltage that it cannot possibly ignite flammable material. By limiting the energy available within the defined hazardous area, electrical equipment can operate safely even amid hazardous mixtures of gasses.

Product selection guide

To find the right part number to purchase please use our selection guide in the shop (link below), product overview under "ordering code" or send our Product Manager Henrik Kudsk a system description and he will guide you to the right part number. Please use the "Product Specification Form" (find it under the "downloads" tab on this product page) and e-mail it to sales@hbproducts.dk.