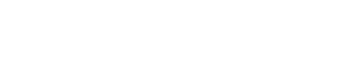

Category: HBX-CO2/HFC for DX and Overfeed Systems

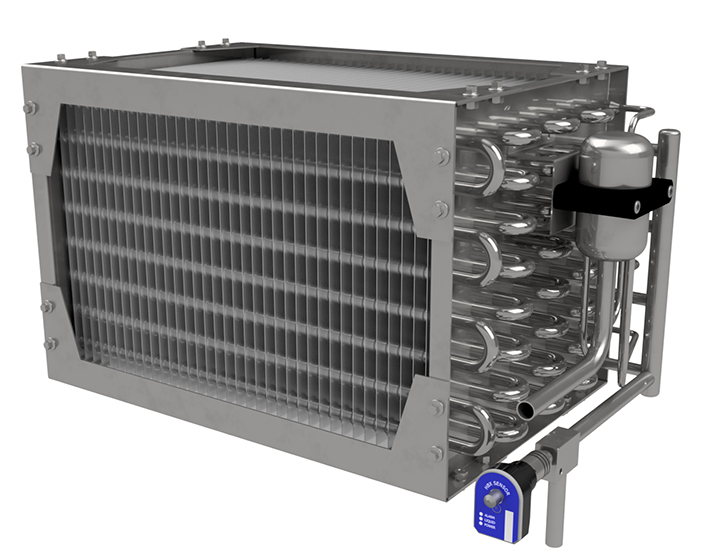

The Angle Rod version is suited for smaller systems and is made in stainless steel. It accepts flow in both directions and is suited for all common refrigerants. For HFC/HFO’s you need to pick an over sized sensor to keep down pressure loss.

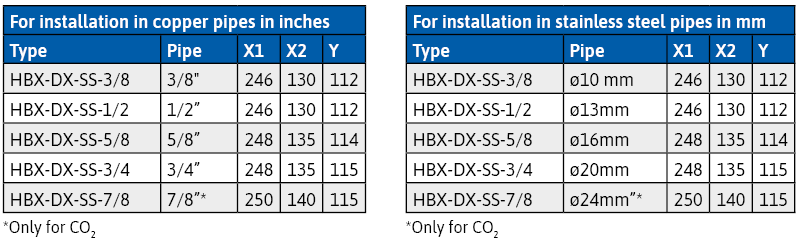

The sensor comes with reductions to compensate for a restricted flow area as standard. The sensor is made in stainless steel and can be butt welded (TIG) or brazed into the system. The sensor element can be removed and cleaned if necessary. The sensor is available from ¼” to 1” pipe size.

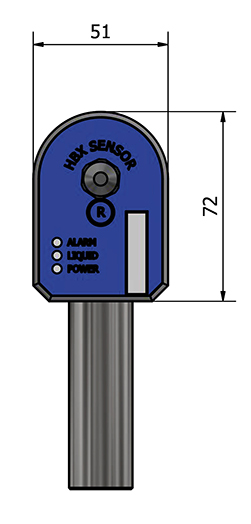

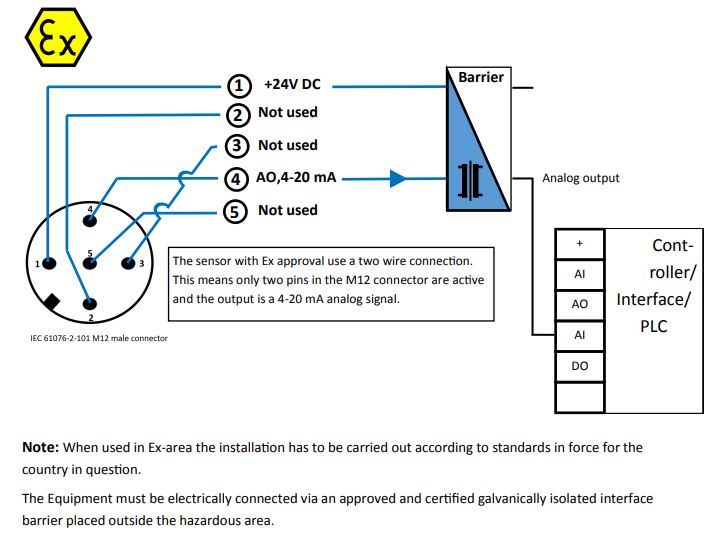

Intrinsically Safe design:

Intrinsically Safe (IS) sensors are designed and wired to work on such a low current and voltage that it cannot possibly ignite flammable material. By limiting the energy available within the defined hazardous area, electrical equipment can operate safely even amid hazardous mixtures of gasses.

Product selection guide

To find the right part number to purchase please use our selection guide in the shop (link below), product overview under "ordering code" or send our Product Manager Henrik Kudsk a system description and he will guide you to the right part number. Please use the "Product Specification Form" (find it under the "downloads" tab on this product page) and e-mail it to sales@hbproducts.dk.