Technische Daten: HBLT-A2 / HBSLT-A2

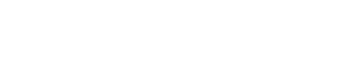

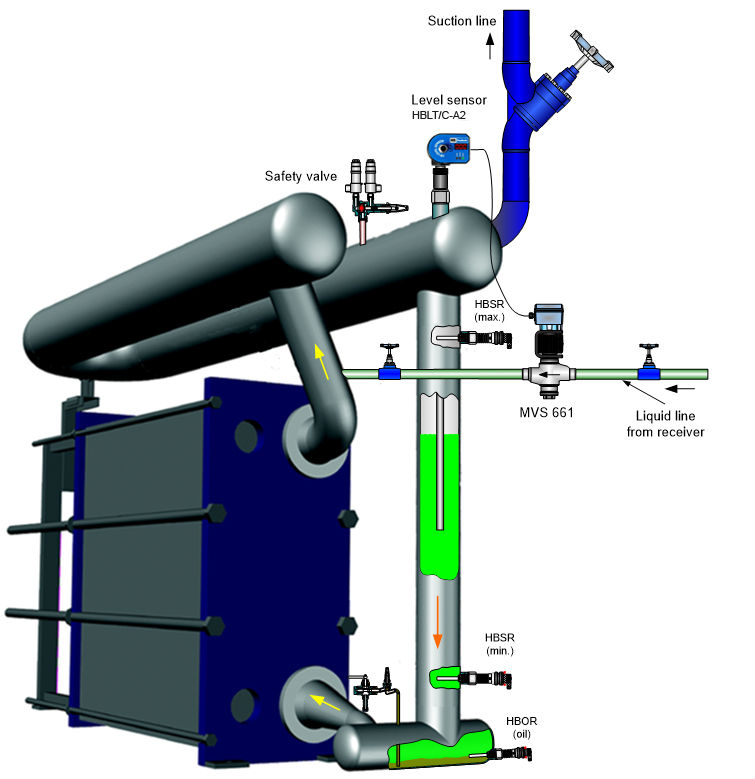

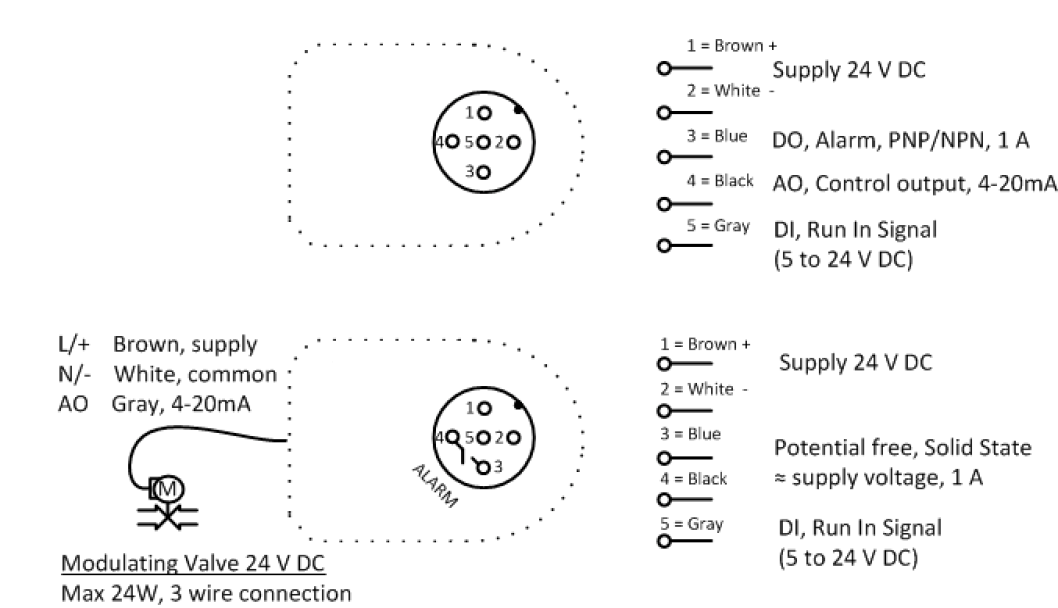

Der kapazitive Sensor HBLT-A2 ist ein Füllstandsensor und dient zur Messung von Kältemittelfüllständen in industriellen Kälteanlagen. Der Sensor sendet ein 4-20 mA Signal: 4 mA im “trockenen Zustand” und 20 mA, wenn der Sensor von flüssigem Kältemittel umgeben ist.Im Unterschied zum HBLT-A1 ist die Elektronik konfigurierbar: Mit Hilfe der HB Software können 3 Parameter eingestellt werden. Ein Display ist vorhanden anstelle eines Bar Graphs; ein integrierter Mikroprozessor liefert ein 4-20 mA Signal, das proportional zum Sensormessbereich arbeitet. Ausserdem hat der Sensor einen integrierten Controller, um autonomy ein Ventil ansteuern zu können. Die erforderliche direkte Kabelverbindung zum Ventil kann auf Wunsch ebenfalls geliefert werden.

Der HBLT-A2 ist ohne Aufpreis, bietet aber mehr Möglicheiten als sein Vorgänger (HBLT-A1).

Der Sensor wird in einer Version ohne integriertes Kabel (HBLT) und einer Version mit Kabel zur direkten Steuerung von Ventilen (HBSLT) geliefert.