Technical data: HBX-CR-IN / HBX-DX-IN

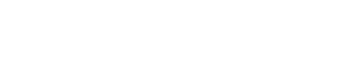

The Vapor Quality Sensors have a new innovative technology which makes it possible to measure the mix between gas and liquid in a refrigerant from 0% gas to 100 % gas - a measurement no other sensor can provide. It consists of a tube, with metal inserts, where the mix of two phases pass through. The sensor measures the dielectric constant of the fluid, and as two different phases (liquid/gas) has different dielectric constant, the mix between the two, can be calculated. The output of the sensor is the “X” value which has a linear relation to the Volume % of liquid in the gas

The sensor offers very precise measurements and provides instant read-outs of the gas quality, making it useable in most evaporators (plate, pipe, and air evaporators).

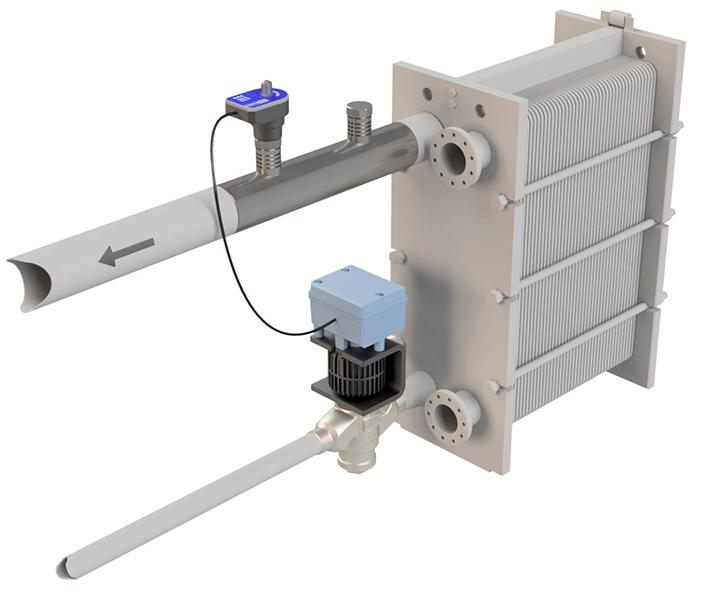

The sensor’s microprocessor also functions as a controller, enabling the direct control of a modulating motor valve, thereby bypassing the external controller or the PLC. The controller can be set up with all the parameters that are necessary for regulating a modulating motor valve or a stepper motor valve. The sensor is available with a cable for direct supply to and control of the motor valve, or as a sensor where the signal is sent to the external controller/PLC.

All vapor quality sensors are suitable for controlling both DX, semi flooded and flooded operation.

Leakage detection for ammonia CO2 cascade systems

The vapor quality sensor can detect ammonia carbamate which is formed when CO2 leak into ammonia. The sensor can be used for both leakage detection and control an evaporator at the same time or just serve as leakage detector. The alarm can both be provided as a digital alarm and via the analog output. For shell and tube heat exchangers the HBAC is normally used.

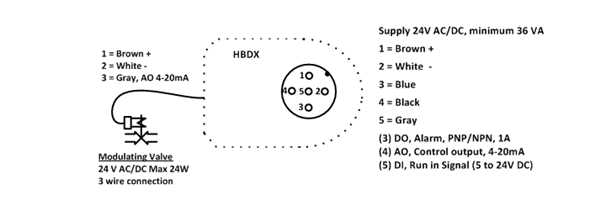

Inline

The straight version called Inline is available from 1” to 2” and the sensor accepts flow in both directions. The pressure loss in the sensor is very low due to the straight flow and smooth internal design. Mounting can be both horizontal and vertical position. The sensor is made in stainless steel and can be butt welded (TIG) or brazed into the system.

Product selection guide

To find the right part number to purchase please use our selection guide in the shop (link below), product overview under "ordering code" or send our Product Manager Henrik Kudsk a system description and he will guide you to the right part number. Please use the "Product Specification Form" (find it under the "downloads" tab on this product page) and e-mail it to sales@hbproducts.dk.