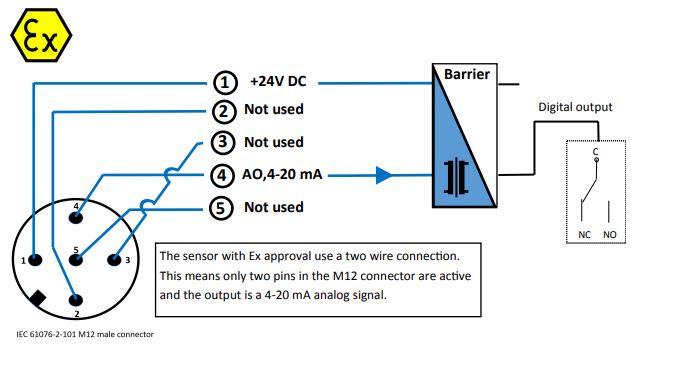

Technical data: HBSR, Temperature range: -40..+70°C

HBSR is a level switch for detecting liquids. It is calibrated so that it is unaffected by spray and of foam. The sensor is designed in stainless steel and can be used in corrosive environments. The sensor is constructed to resist high pressure and high temperatures. The HBSR switch is only suitable for installation in steel tanks or steel pipes.

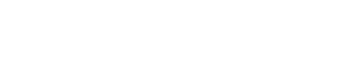

The switch must be supplied with 24 V DC through an Ex-barrier, which must be an approved and certifided galvanically isolated interface barrier placed outside the hazardous area. The switch is a 2-wire design with analog output which either will be 4 (no liquid detection) or 20 mA (liquid detection). The digital input on the PLC shall be connected to the Ex-barrier. The Ex-barrier is not sccope of supply.

The sensor can be set-up for liquid type in the HB-Tool which can be downloaded from our web-page. See HB-Tool. It is as well possible to switch from NO to NC type in the HB-tool. Diagnostic is as well a possibility with the tool. The programming must be carried out in an non hazardous area.

The sensor range include sensors for zone 0 and 1 according to ATEX/IECEx. The sensors can be used in device category 1G and temperature class T1...T6.

A 5 m cable with M12 plug type IEC61076-2-101 is included.