Technical data: HBLT-W-Wire & HBSLT-W-Wire

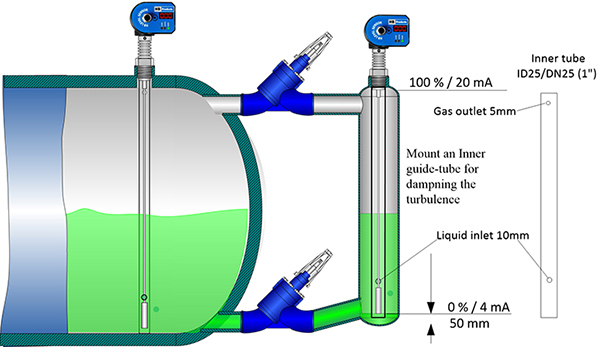

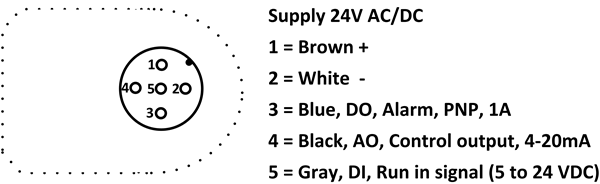

HBLT-W-Wire is a capacitive sensor for level measurement of HFC refrigerant in industrial refrigeration systems. The sensor has an output signal of 4-20 mA, which is proportional with 0 and 100%. Its output signal is 4 mA for an empty container and 20 mA for a full container. HBLT-W-Wire can be adjusted in length to the current application.The sensor element consists of a 2mm steel wire as well as a Teflon tube. Both parts are provided with a length of 4 m and can be shortened with diagonal cutters or other pliers. HBLT-W-Wire can be used in connection with the HBLT-C1 controller for controlling pumps.

The sensor is delivered in a version without integrated cable (named HBLT-Wire) and a version with cable for direct control of valves (named HBSLT-Wire).

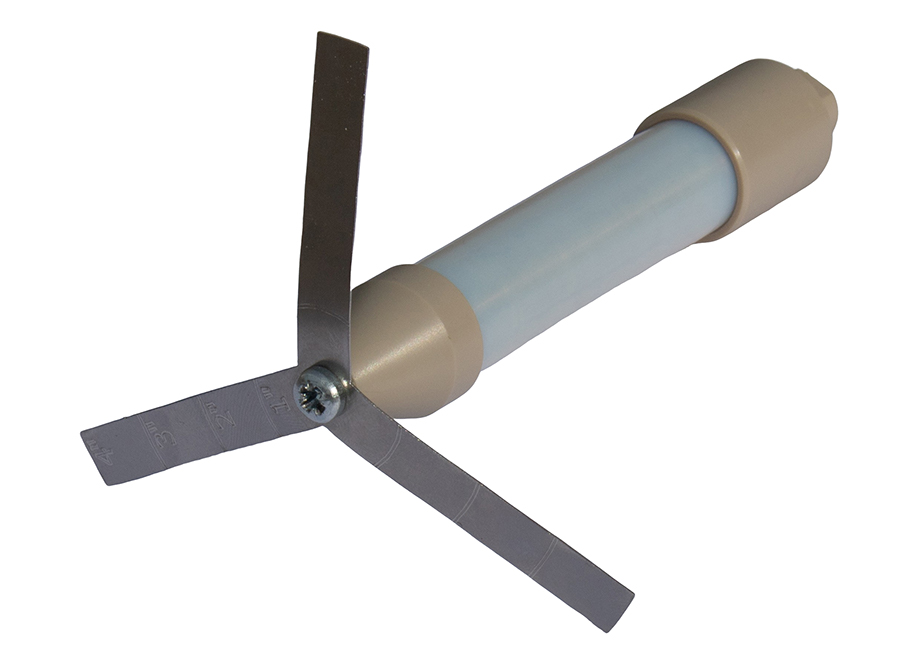

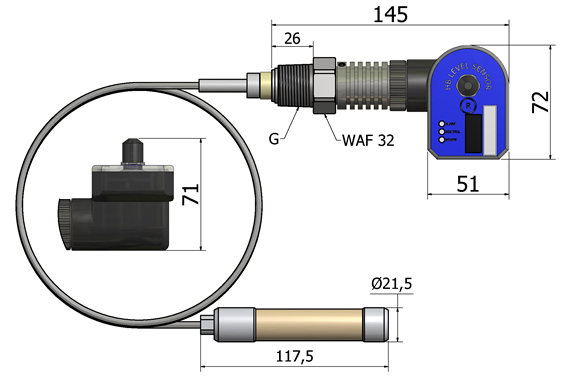

HBLT-WIRE - Counterweight with adjustable center position spring

Under turbulent conditions, the counterweight for the HBLT-WIRE can be supplied as a spare part with an adjustable center position spring. The center position spring is delivered with cutting marks so it can be adapted and cut to the dimension of the stand pipe.